UK LEADERS IN

PRECISION WIRE EROSION

Leveraging state-of-the-art Sodick Wire EDM technology, we deliver unparalleled accuracy for the most complex components. From aerospace to motorsport, we cut with absolute precision.

Trusted by Industry Leaders

WHEN STANDARD MACHINING

ISN'T ENOUGH

Many engineering projects involve intricate shapes, extreme tolerances, or materials too hard for traditional CNC milling or turning. These challenges can lead to production delays, compromised quality, and increased costs.

When you need to cut complex profiles, create sharp internal corners, or machine pre-hardened components without inducing stress, you need a more advanced solution.

THE CTS SOLUTION

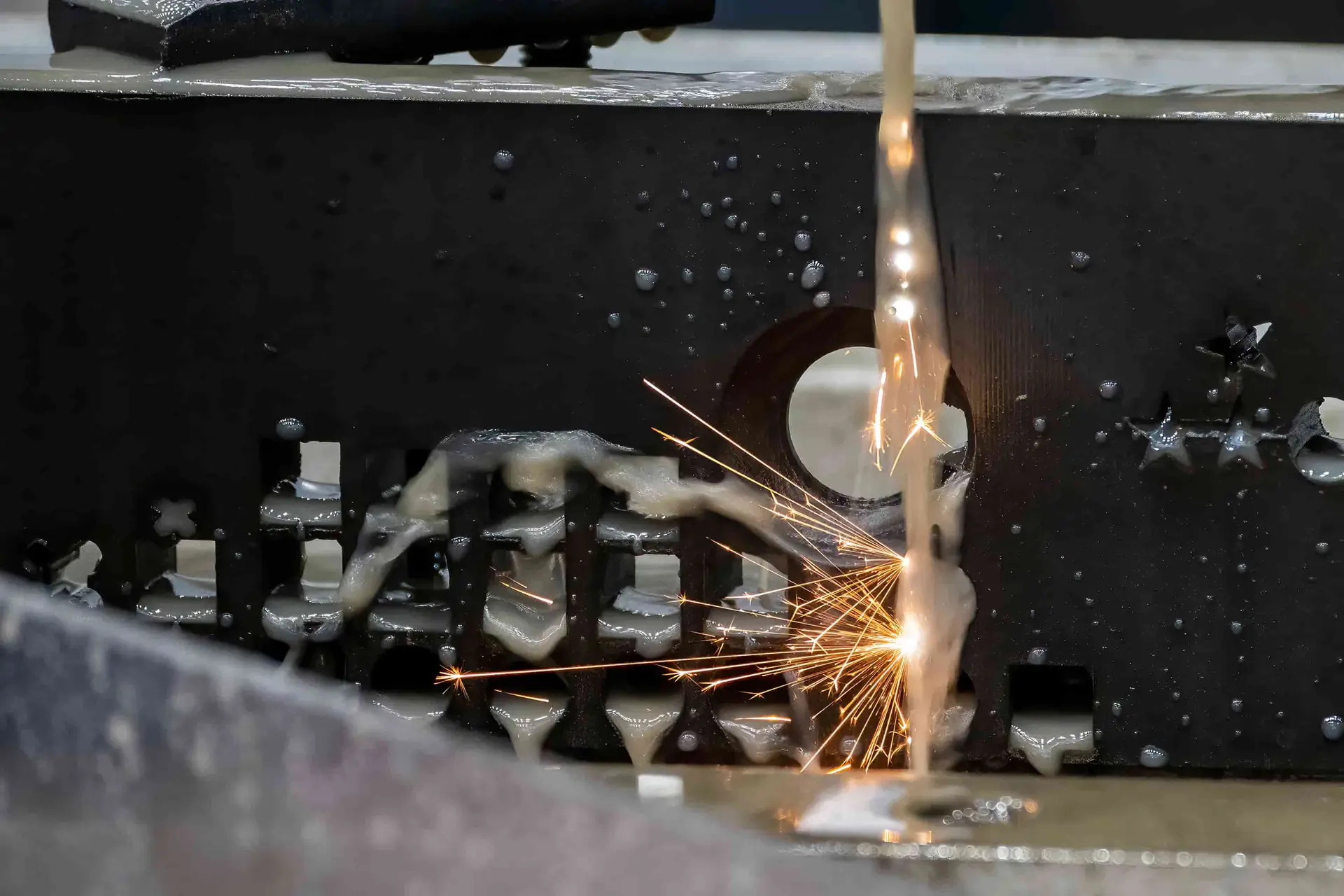

Our specialist subcontract wire erosion service transforms complex designs into reality. Using a precisely controlled electrical spark, we erode conductive material with micron-level accuracy—non-contact, force-free, and flawless.

THE SODICK ADVANTAGE

Why we choose Sodick: The undisputed leader in EDM technology.

CTS (SODICK LINEAR)

- Friction-Free DriveNo mechanical contact means zero wear and sustained accuracy for decades.

- Zero BacklashDirect drive technology eliminates the backlash found in ball screws.

- High Response SpeedInstantaneous reaction to spark gap conditions for a perfect finish.

STANDARD (BALL SCREW)

- Mechanical WearBall screws degrade over time, leading to loss of precision.

- Backlash IssuesMechanical play requires constant compensation and maintenance.

- Slower ResponseMechanical lag results in slower cutting and rougher surfaces.

Linear Motor Tech

Vibration-free cutting for superior accuracy and surface finish.

Glass Scale Feedback

Guarantees absolute positional accuracy on all axes.

Submerged Cutting

Ensures thermal stability and a flawless finish on every part.

Advanced Tapering

Achieve complex angles with perfect precision.

SODICK AQ750L:

LARGE-SCALE CAPACITY

Designed for heavy and oversized workpieces, our fixed-table design ensures that even the heaviest components can be machined without compromising sub-micron precision.

THE CHALLENGE: AEROSPACE TITANIUM COMPONENT

A leading aerospace client required a complex 400mm thick titanium component with a tolerance of just ±5µm. Traditional machining induced too much stress, warping the part.

Sodick AQ750L Submerged Cutting

100% Pass Rate on CMM Inspection

QUALITY ASSURANCE

- Mitutoyo CMM Verification

- Faro Arm Inspection

- Full Traceability Reports

- ISO 9001:2015 Certified

INDUSTRIES WE SERVE

Delivering critical components for the world's most demanding sectors.

AEROSPACE

Machining exotic alloys like Inconel and Titanium with zero stress or thermal distortion.

MOTORSPORT

Rapid turnaround for high-performance parts where weight reduction and precision are critical.

MEDICAL

Burr-free micro-machining for surgical instruments and implantable devices.

NUCLEAR

Handling hazardous materials with strict adherence to safety and traceability standards.

TOOLMAKING

Creating complex punch and die sets with hardened tool steels up to 65 HRC.

OIL & GAS

Robust components designed to withstand extreme pressures and corrosive environments.

WIRE EROSION FREQUENTLY ASKED QUESTIONS

Expert answers to your technical questions.

READY TO DISCUSS

YOUR PROJECT?

Get a fast, no-obligation quote for your wire erosion needs. Our team of engineers is ready to review your design and provide expert guidance.

CALL US

+44 1745 369963EMAIL US

[email protected]VISIT US

Unit A, Cefndy Road, Rhyl,

Denbighshire, LL18 2TT

Unit A, Cefndy Road, Rhyl, Denbighshire, LL18 2TT